SVARN WIND ENERGY CABLES

Maximise Efficiency. Minimise Power Loss.

Cable design is integral to optimising the efficiency and lifespan of wind energy projects.

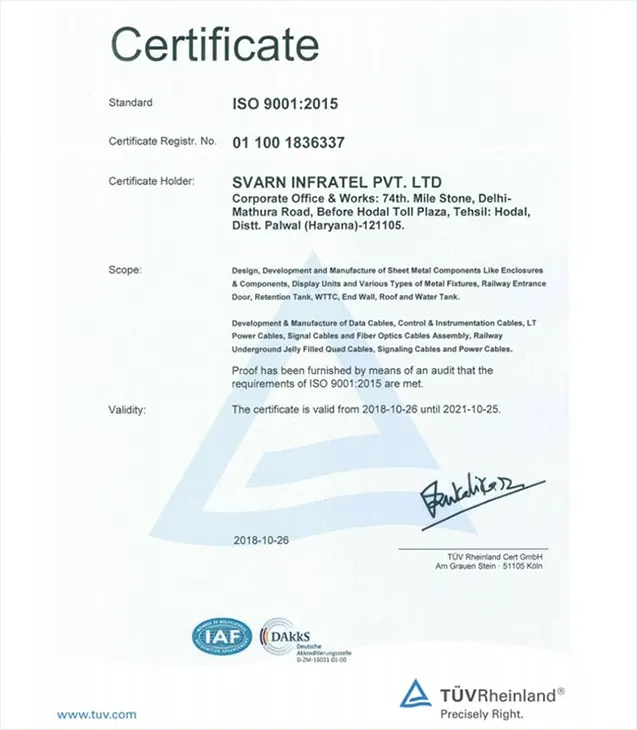

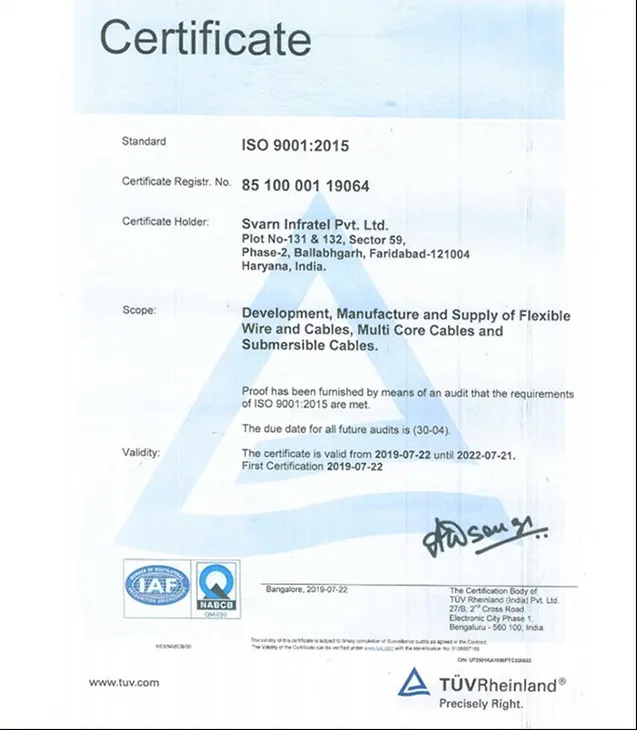

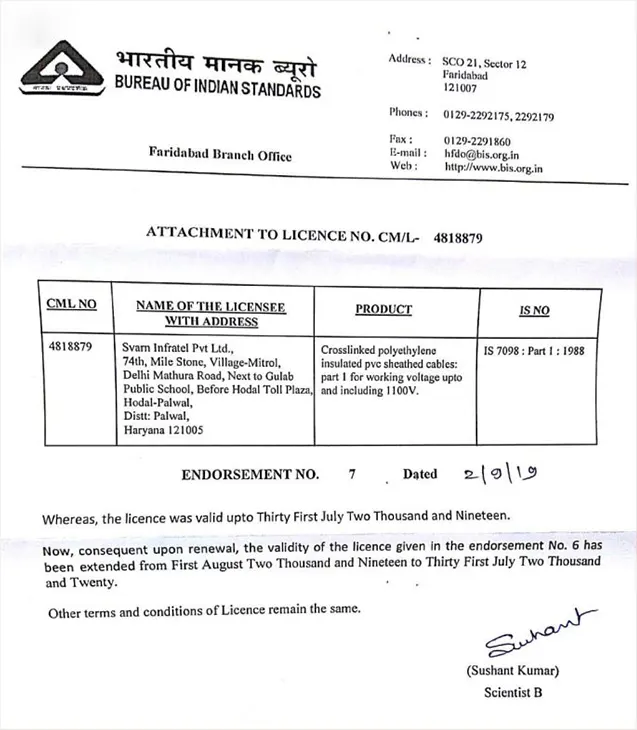

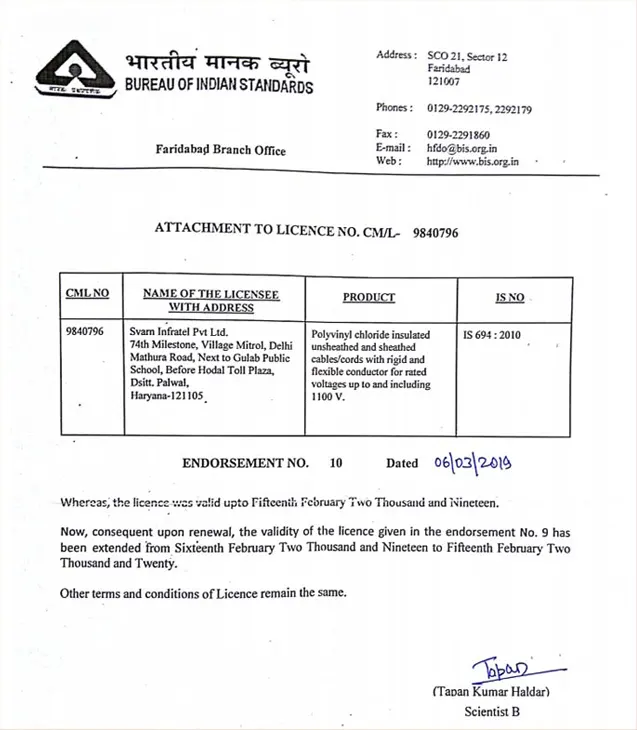

At Svarn, our focus is on manufacturing cables that minimise power loss, maximise transmission efficiency, and withstand extreme weather conditions, whether deployed in onshore or offshore wind farms. Our dedication to product excellence is upheld by our advanced in-house production and testing facilities, enabling us to provide customers with a diverse range of high-quality products conforming to international standards.

RUBBER LOOPED SCREENED CABLE

Svarn rubber looped screened power cables are specifically engineered to meet the demands of harsh conditions typically encountered in wind turbines. Their design focuses on durability, flexibility, and resistance to mechanical stress, making them ideal for outdoor installations where they may be subjected to environmental elements like wind, rain, and temperature variations.

RUBBER LOOPED UNSCREENED CABLE

Svarn rubber looped unscreened power cables are tailored for specific application conditions within wind turbines, particularly for use in fired and mobile installations situated indoors. These cables are engineered to meet the unique requirements of indoor environments, where they may be subject to different stresses and environmental factors compared to outdoor installations.

SINGLE CORE COPPER TOWER CABLE

Svarn single core copper tower cables are designed to meet the rigorous demands of wind farm installations, whether they are fixed or mobile. XLPO (cross-linked polyethylene) insulation provides excellent electrical properties, thermal stability, and resistance to environmental factors, making it well-suited for use in both stationary and mobile wind turbine setups.

SINGLE CORE COPPER E-BEAM TOWER CABLE

Svarn single core copper e-beam tower cables are specialised cables designed for use in wind turbine applications, particularly within the tower structure. These cables are specifically engineered to meet the unique requirements of wind turbine installations, providing efficient power transmission while withstanding the mechanical stresses and environmental conditions.

SINGLE CORE ALUMINIUM TOWER CABLE

Svarn single core copper tower cables are designed to meet the rigorous demands of wind farm installations, whether they are fixed or mobile. XLPO (cross-linked polyethylene) insulation provides excellent electrical properties, thermal stability, and resistance to environmental factors, making it well-suited for use in both stationary and mobile wind turbine setups.

COMPREHENSIVE CABLING SOLUTIONS

FOR WIND POWER APPLICATIONS

CONTROL CABLES

Flexible shielded cables with 2 to 100 cores are versatile components used in various applications, including carrying energy and low-frequency signals to control motor drives or generators in wind turbines. These cables play a crucial role in transmitting power and control signals, enabling functions such as braking, positioning, and optimizing rotor RPMs.

POWER & CONTROL CABLES

Unarmoured cables suit fixed installations without mechanical risk, while armoured cables are recommended for areas needing enhanced mechanical protection and EMC screening. Svarn’s highly flexible cables are ideal for narrow spaces with tight bending requirements. Multicore cables with sectoral conductors offer additional space and weight savings on cable trays.

FIELDBUS, COAXIAL CABLES

Can Bus or Profibus cables have fixed impedance and transmit an extremely precise digital signal to control all essential PV array functions, like motors, rudder and hydraulic systems. Coaxial cables are usually used for on-board high frequency data transmission (communication equipment, radar, and instrumentation) and also carry video signals for surveillance cameras.

LV FIXED INSTALLATION CABLES

Copper cables can be single or multicore, featuring EMC screening. In contrast, single-core aluminium cables are larger but weigh half as much, making them more cost-effective and easier to handle and install, especially in tall towers. Svarn provides low-voltage aluminium cables to major wind energy OEMs.

FIBER-OPTIC CABLES

Svarn’s robust and halogen-free fibre optic cables ensure high data transmission capacity for monitoring and control in energy-dense environments, providing Electromagnetic Compatibility (EMC). These cables are exceptionally flexible and can withstand high torsion, making them suitable for demanding applications. With large cores (200 microns), connectivity is made easier, ensuring reliable performance in critical operations.

FIRE RESISTANT CABLES

In a fire emergency, onboard equipment must remain operational to aid safe evacuations. Svarn excels in innovative fire-resistant cable design for control and power applications, vital for safety systems like emergency lighting, fire detection, and door opening mechanisms. These cables ensure electrical circuit integrity for a specified period post-fire onset, enhancing safety in wind farms and protecting lives and infrastructure from fire risks.

ELECTRONIC AND DATA TRANSMISSION CABLES

Thermoplastic Modified (TPM) cables, with 2 to 5-core sensor multicore options, measure wind speed, temperatures, and performance parameters. Additionally, 2-core Fieldbus cables control electronic and mechanical devices alongside energy cables. Two-core Profibus cables offer speeds up to 12 Mbit/s for precise control services, and data transmission cables provide Industrial Ethernet speeds. All cables are shielded for Electromagnetic Compatibility (EMC) protection.