The Indian automotive sector is a driving force, contributing 7.5% to India’s overall GDP and a remarkable 49% to India’s manufacturing GDP.

Even in adversity, the Indian automotive industry showed unbelievable resilience, with an impressive 23% growth, contributing 2.3% to India’s GDP.

By 2026, it is estimated that the auto parts exports business will contribute about 7% to nation’s GDP. Svarn Group recognises this opportunity and is committed to the automotive sector’s growth.

Automotive Manufacturing

GHILOTH (RAJASTHAN) PLANT

Our investments are geared towards technology. Establishing an E-beam facility deploying superior manufacturing technologies for world-class products for domestic and overseas auto manufacturers.

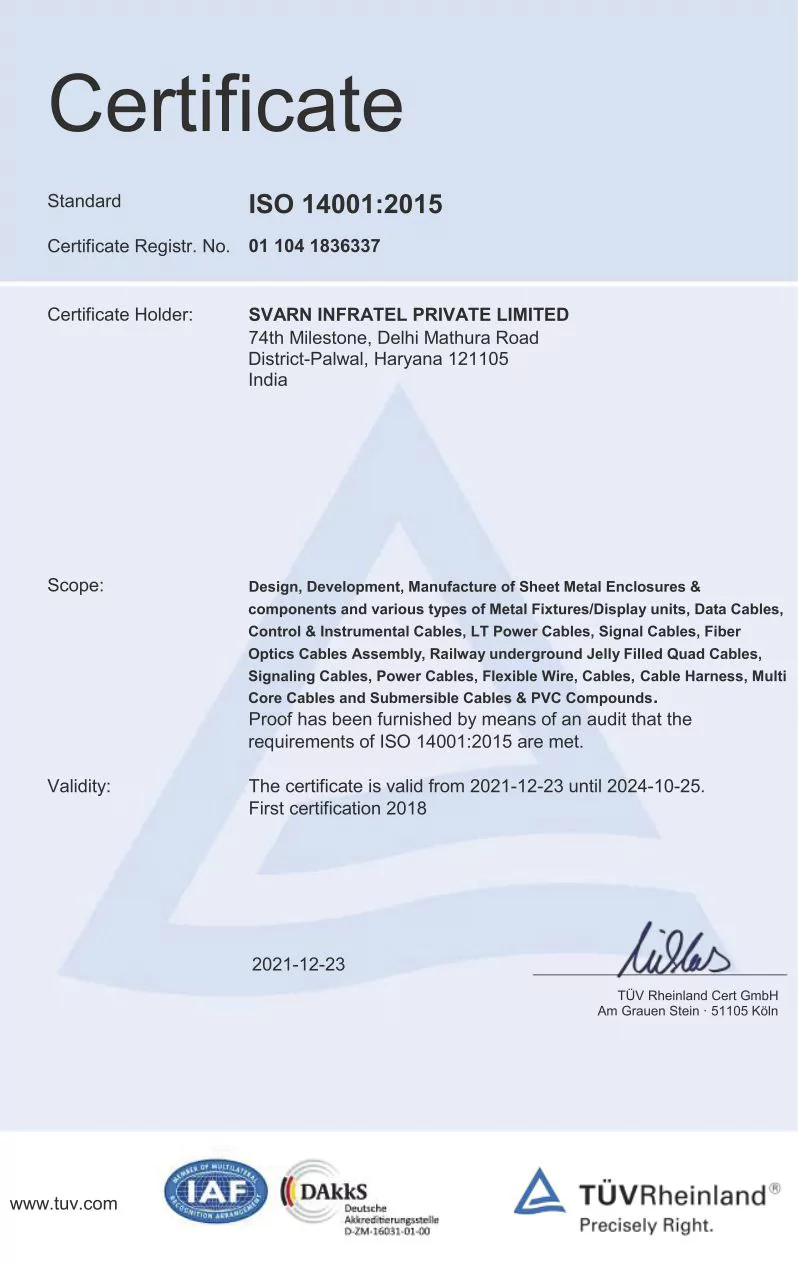

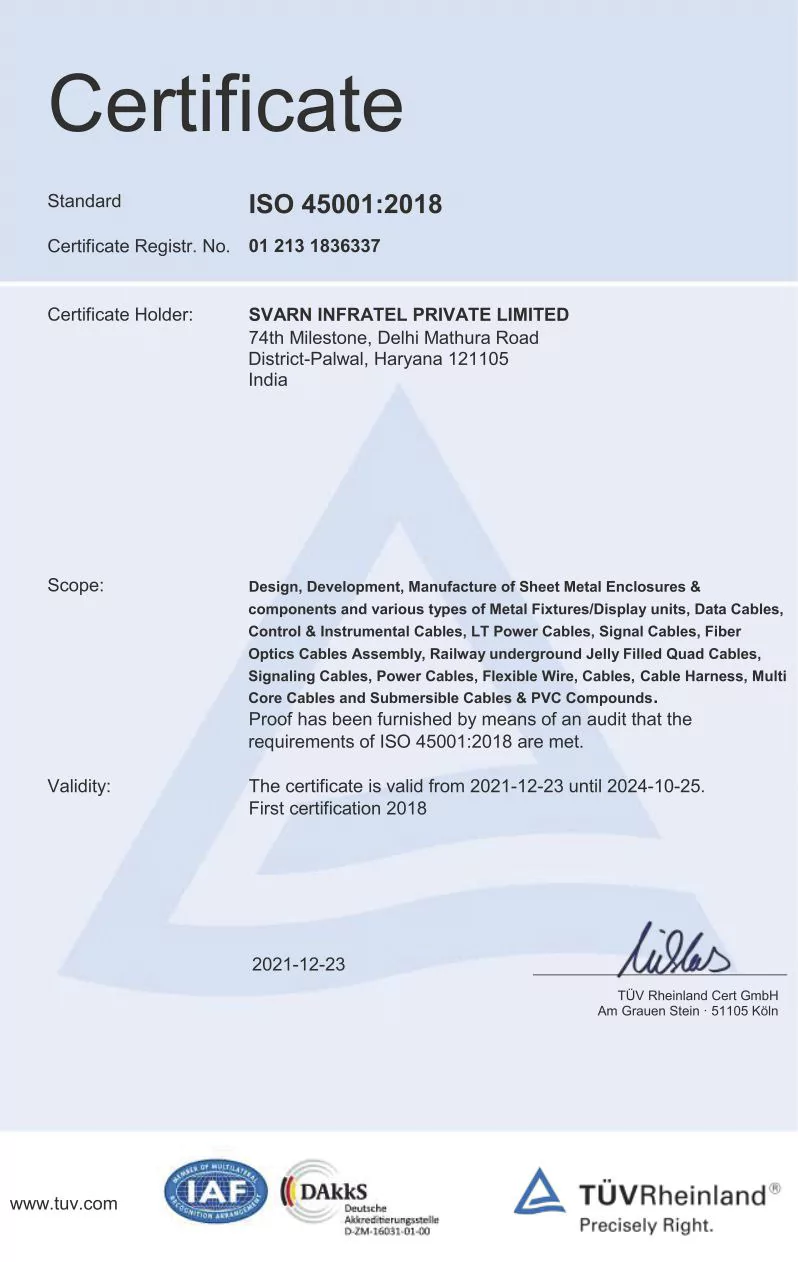

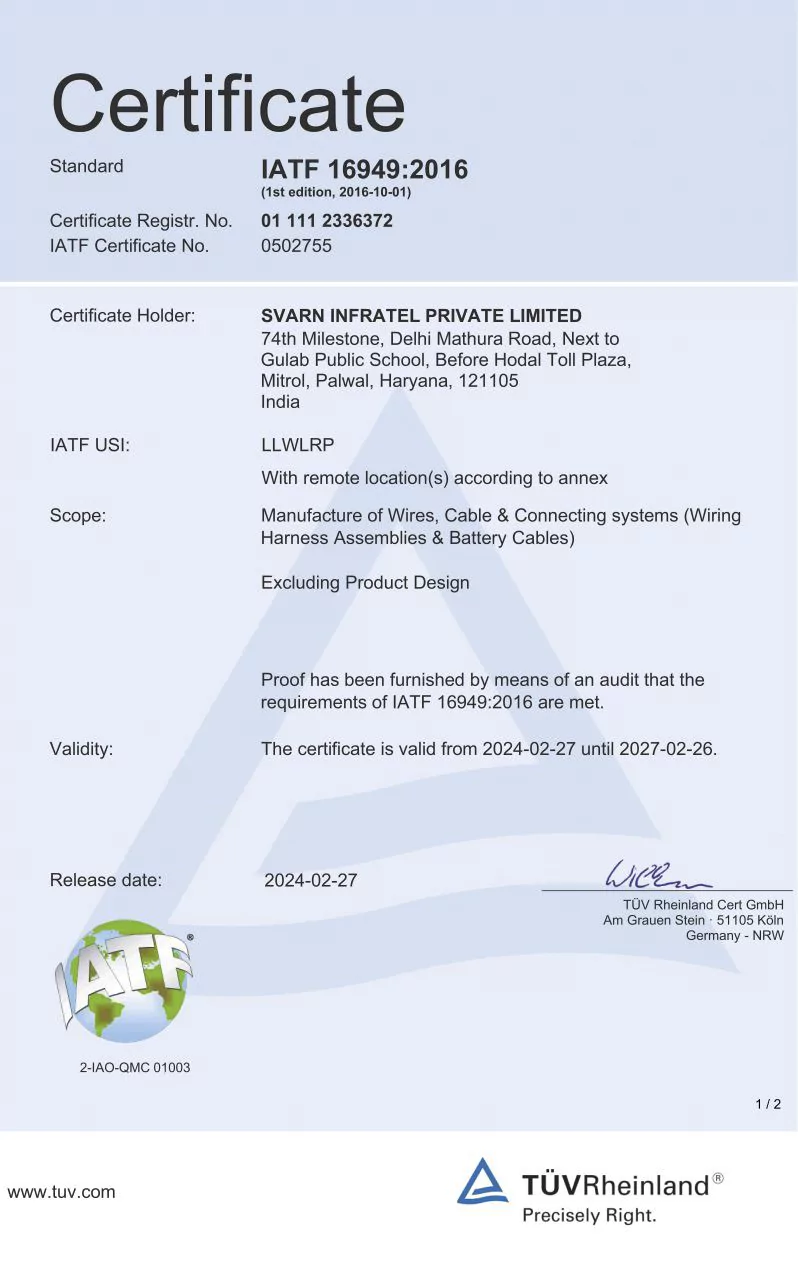

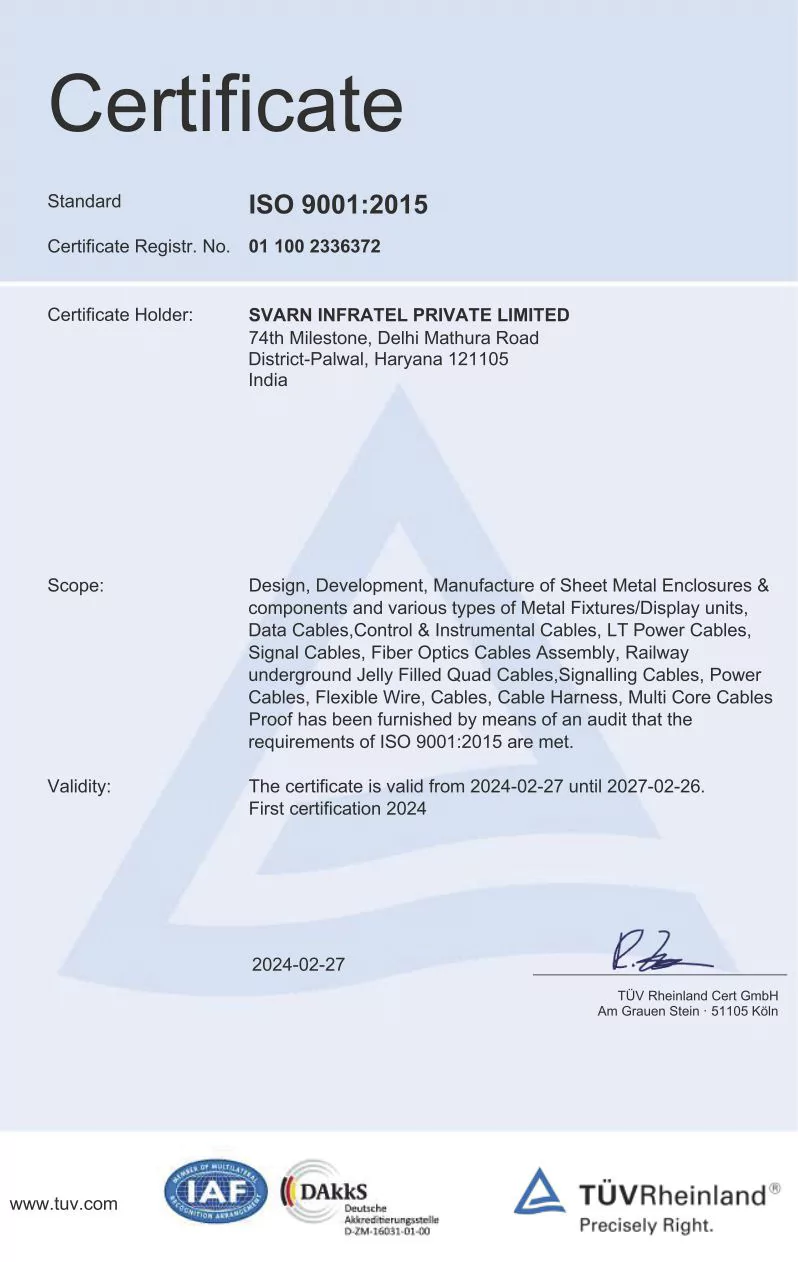

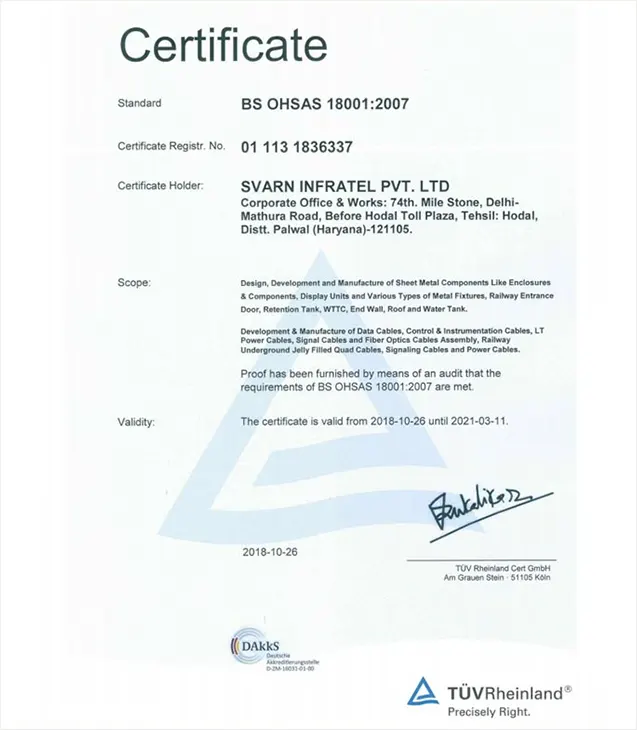

SVARN Automotive offers a comprehensive product range with a wide variety of approvals from OEMs and Tier 1 customers.

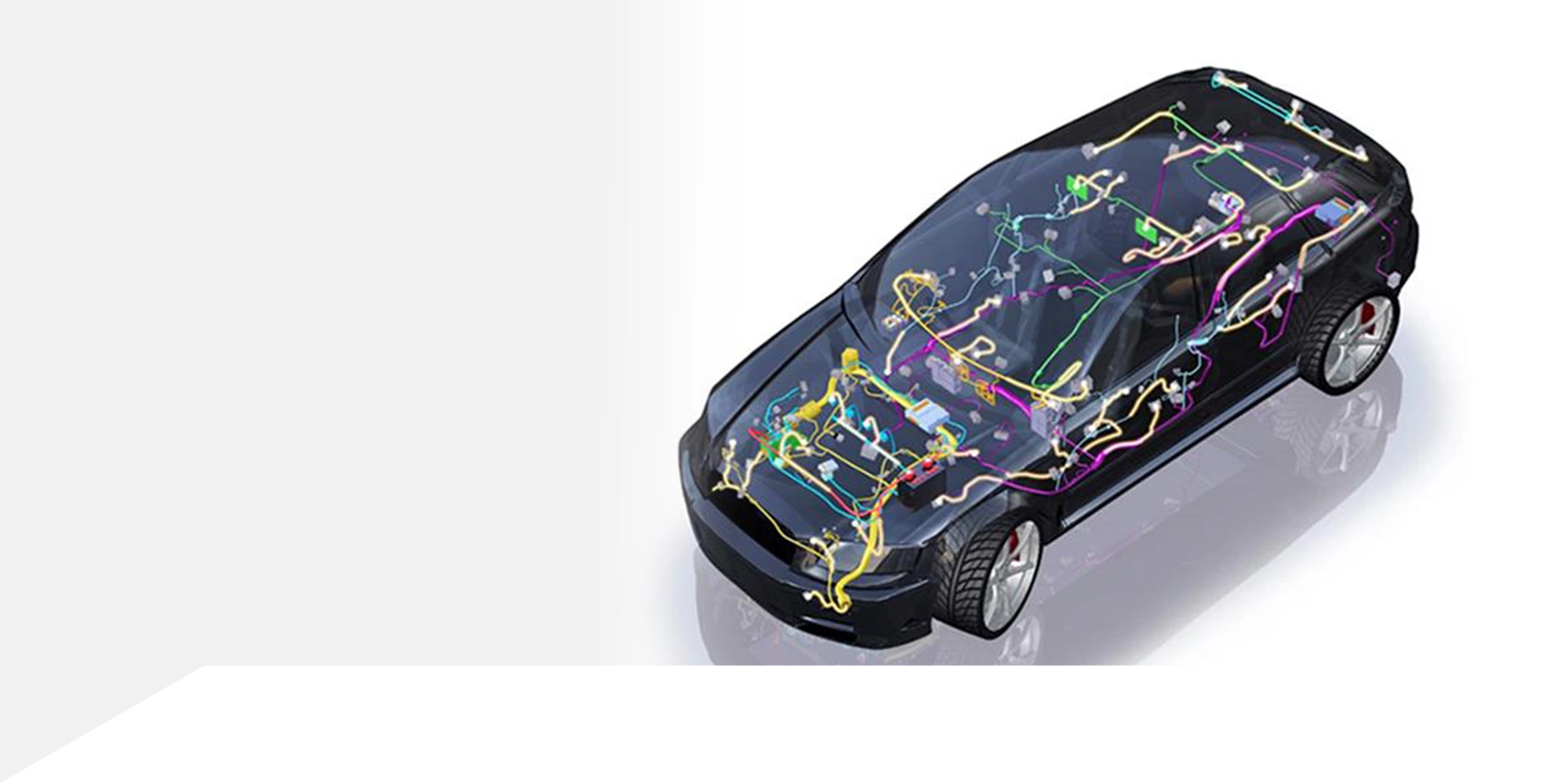

SVARN Automotive is a full-service provider for all types of automotive wiring harnesses.

As a subsidiary brand of the SVARN Group, the Wiring Harness business unit works on innovative solutions which have grown over decades.

Our passion is to think ahead with holistic solutions for customer-specific requirements.

Components driving the future forward

LV Wiring

Our core competencies

We are for specialised products thanks to continuous development. We shape the megatrends of e-mobility, autonomous driving and connectivity.

Full-service provider for all types of automotive wire harnesses.

Interdisciplinary concept development and implementation from a single source (inquiry, installation space analysis, production of prototypes, pre-series production, optimisation up to series production maturity, series process development, prototype qualification, series support).

- System specialist (with in-house cable and manufacturing expertise).

- Advanced engineering and continuous improvement.

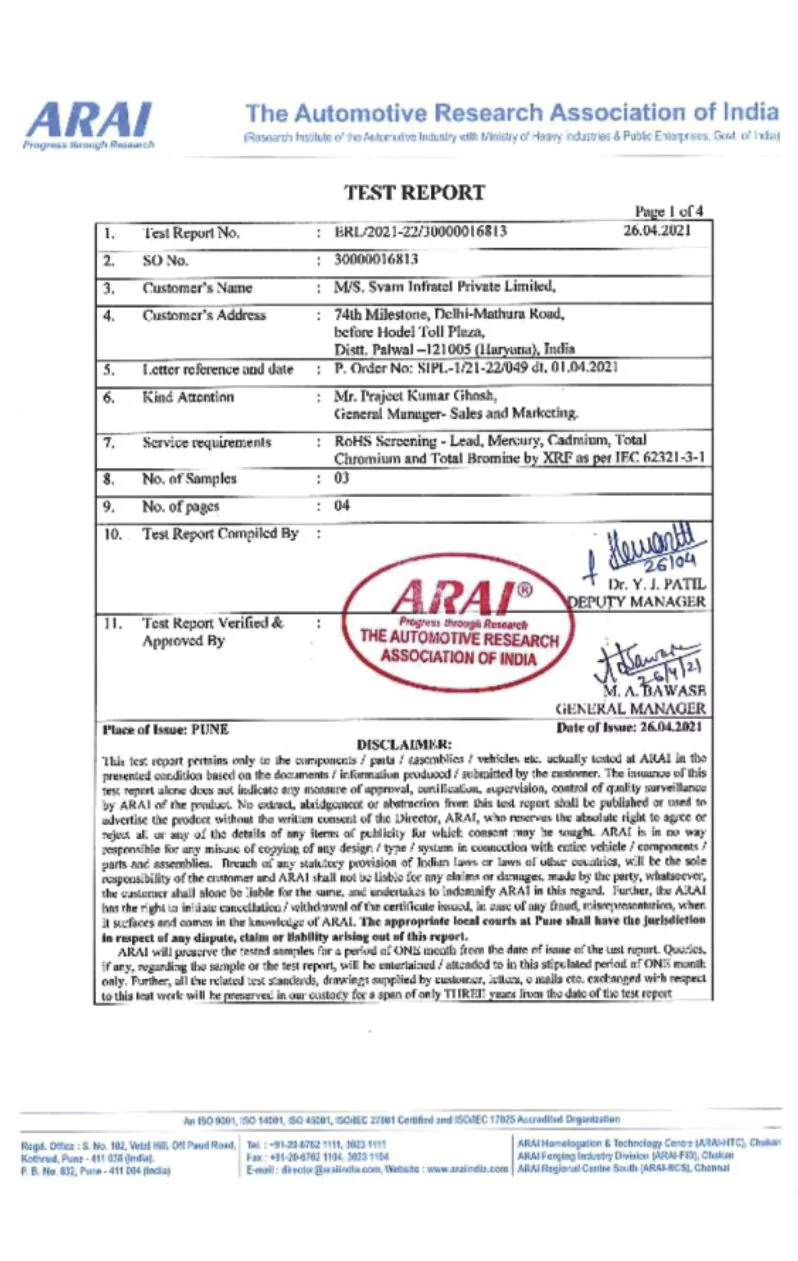

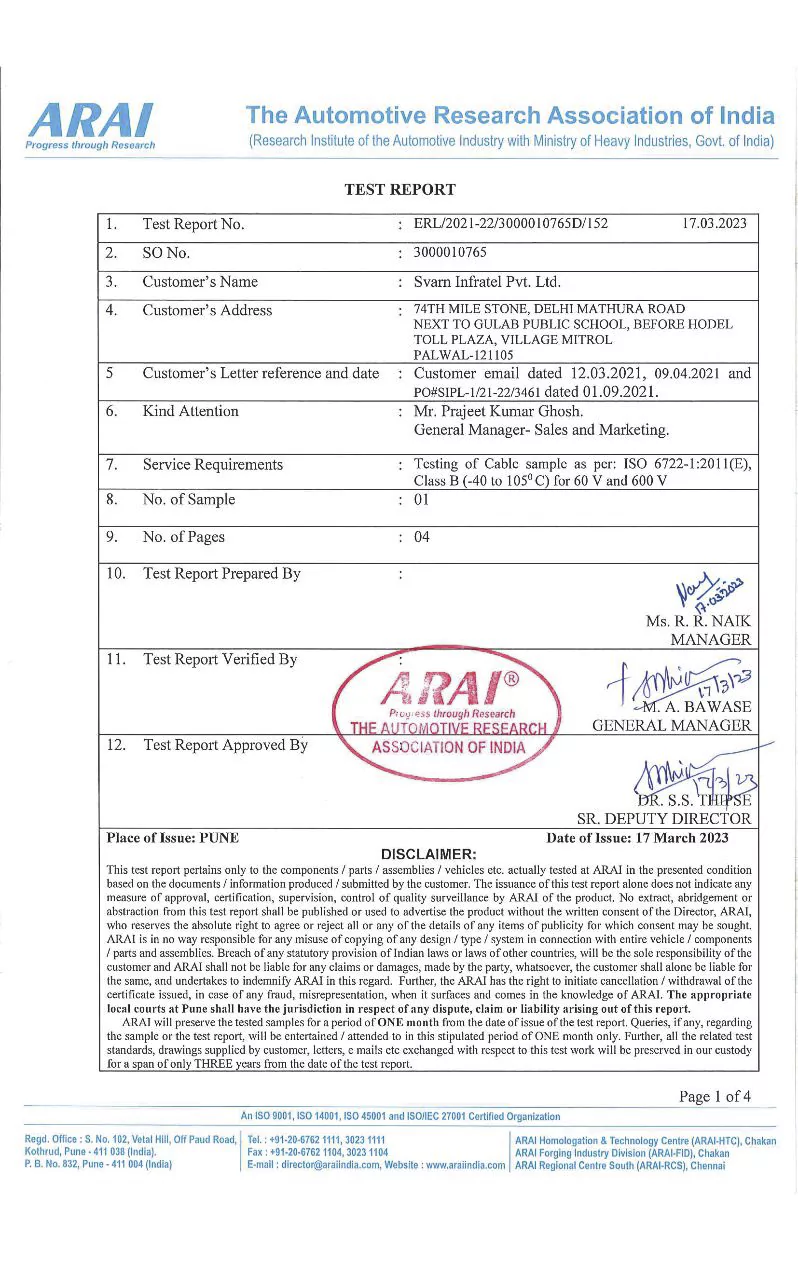

Technical testing department: In-house testing and validation systems for testing mechanical, electrical, and chemical environmental influences according to common standards.

We offer an all-round service from conception and development to design, prototyping, and series production at our modern production sites.

On-Line Quality Checks

Process Set up an inspection

- Crimp Height Monitoring/ Pull Load Testing

- As per the standardization of the applicator

In process inspection

- Hourly basis, the start and end of each batch

100% Continuity Testing of wiring harness

- Electrical continuity with online printing

- Absence of inversion

- Inter-connection short circuit

- Presence of fuse, relays, and diodes

- Waterproofing testing

Design & Development of a Complete Wiring Solution

Engineering capability

- Design

- Development

- Lab Testing

- Component Development

Can design develop complete wiring solutions

- Circuit Schematic

- Connection System

- Routing and Packaging

- DFMEA

Availability of appropriate Software

- Functionality

- Load Categorisation

- Circuit Protection

- Wire Type/ Size Selection

- Voltage Drop

- Optimized Design