Facility & Resource

Svarn Cables are manufactured at a state-of-the-art, fully-integrated facility spread over 125,000 square feet in Palwal, Haryana (70 km from New Delhi). The facilities currently employ more than 450 personnel, including electrical & chemical engineers, product specialists, quality supervisors and technically qualified production staff.

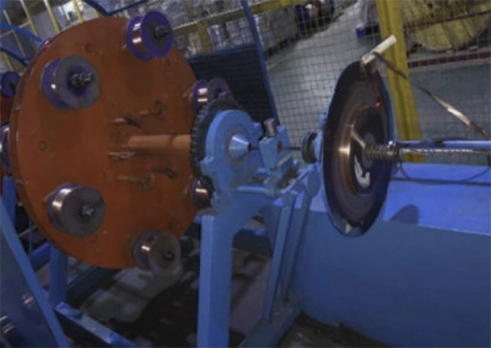

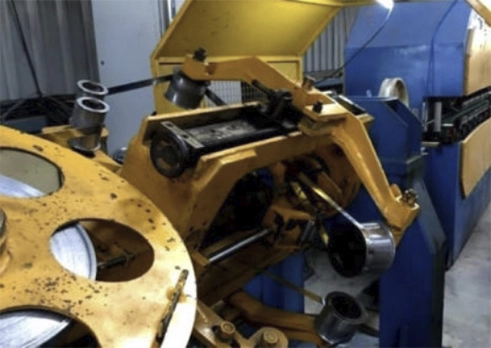

Types of Machines used in Svarn

- Upgrade Technology Rod Break Down (RBD) Machine

- NIEHOFF (GERMAN) Wire Drawing Machine with the latest technology Diamond Tools /Dies

- NIEHOFF (GERMAN) Wire Bunching Machine with Automatic Wire Break Sensor

- Latest Technology Extrusion Line

- Braiding Facility

- Screening Machine

- Double Steel Tape Machines

Manufacturing Product Portfolio

- LT Power Cable

- Control/Railway Signalling Cable

- Telecom Cable

- Category Cable

- Domestic Wire

Capacity

- 1,000 KM/ Month

- 2,000 KM/ Month

- 1,500 KM/ Month

- 1,200 KM/ Month

- 200,000 Coils/ Month

Customer Connect

Our primary attention is on achieving customer delight by delivering not only superior products but also new and innovative range of products to complement our customers’ needs. At Svarn, we flourish by working with our customers to develop new technologies and products to match the ever-changing needs of the industry and its users.

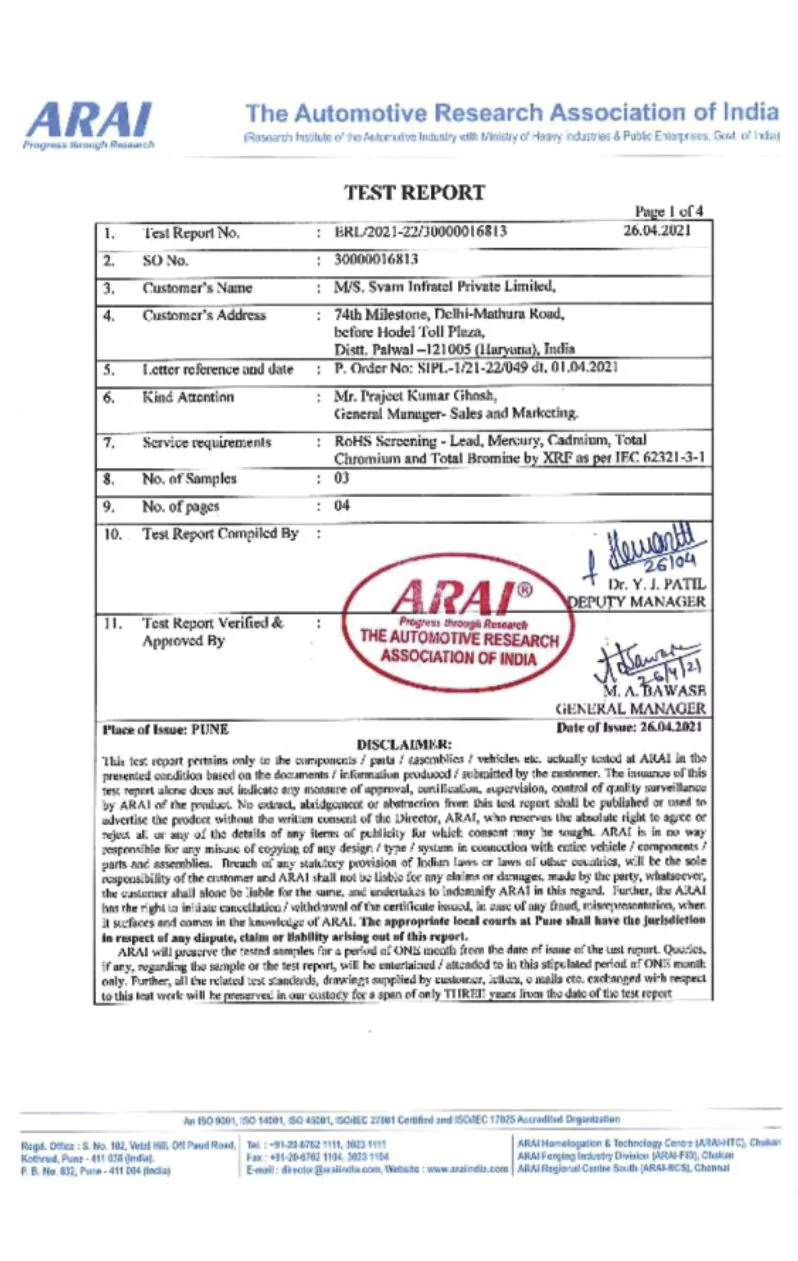

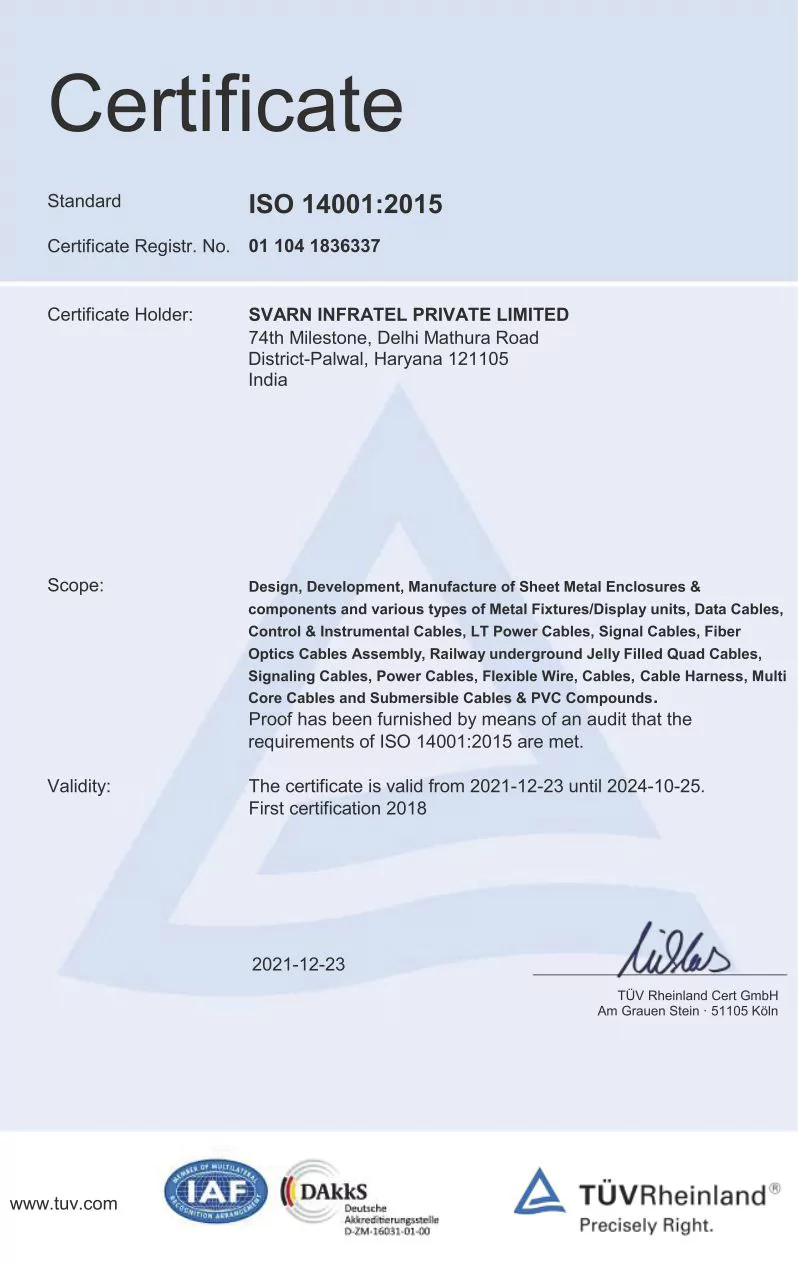

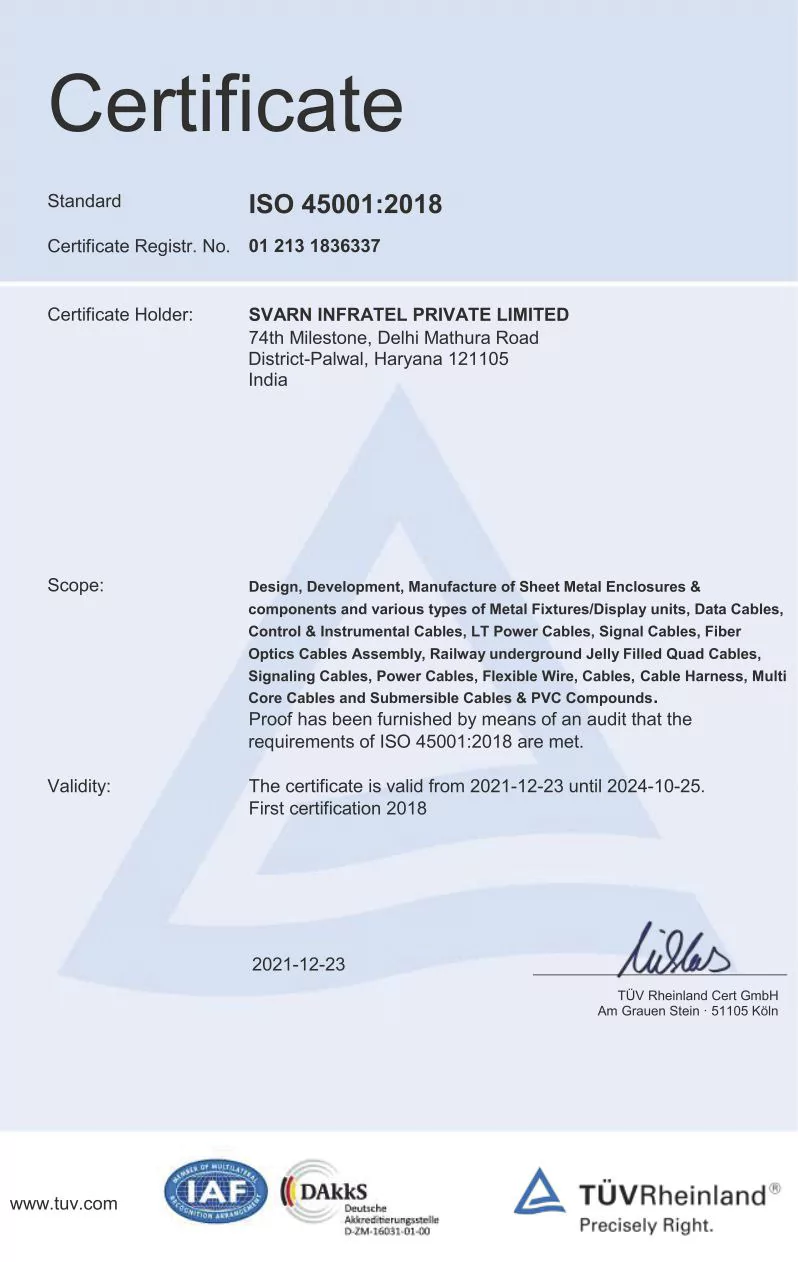

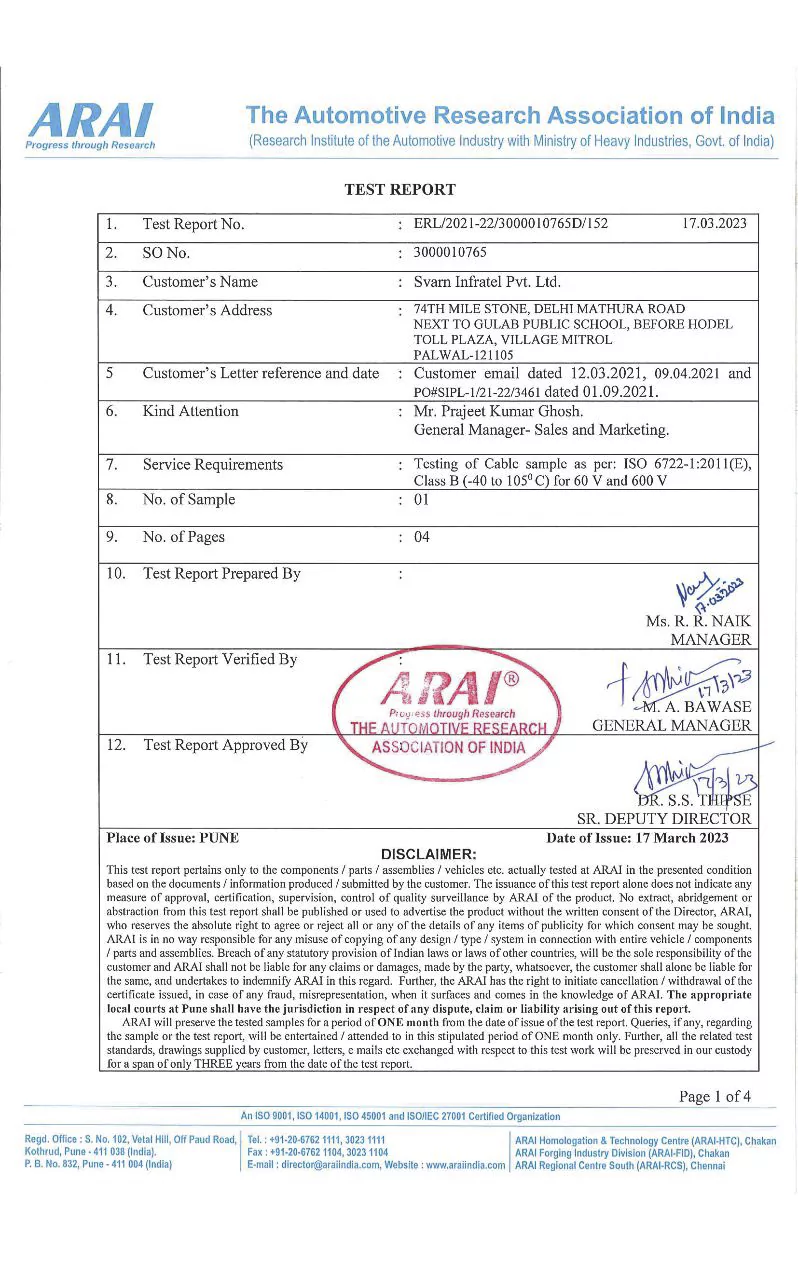

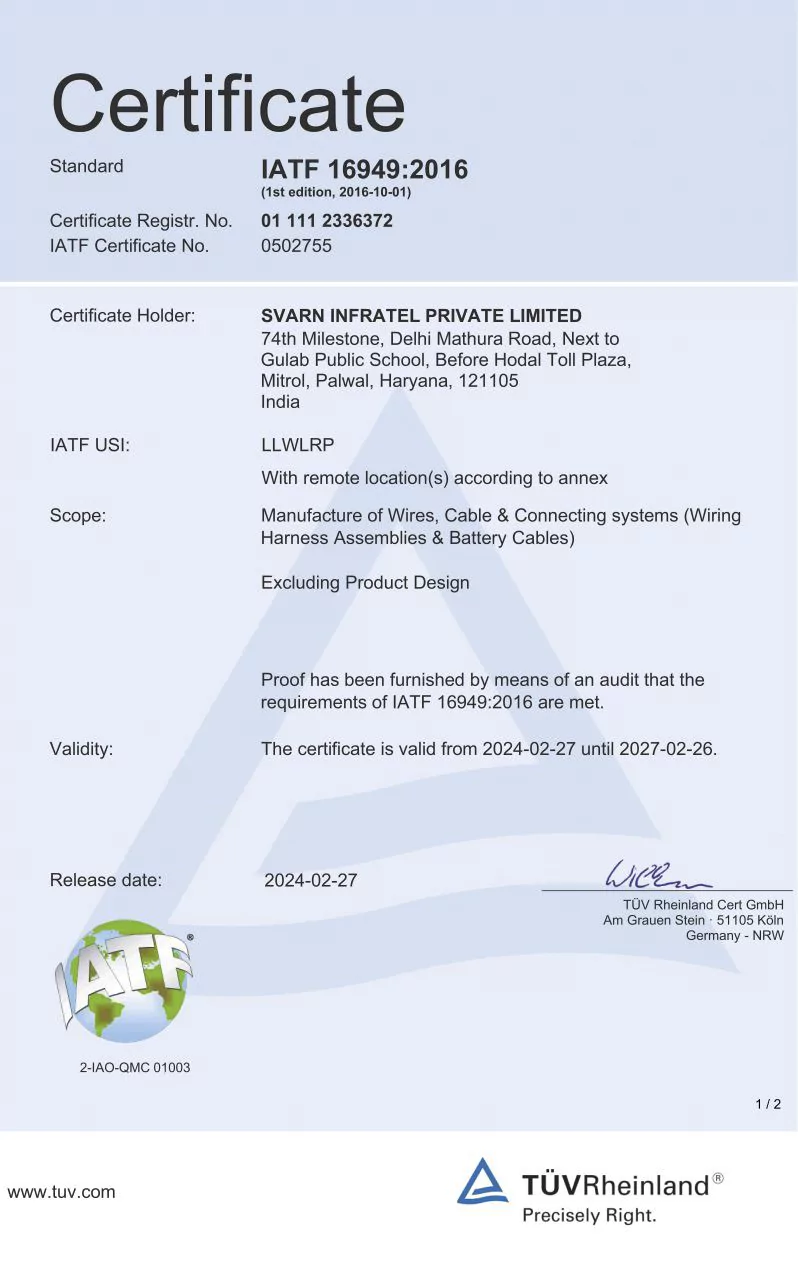

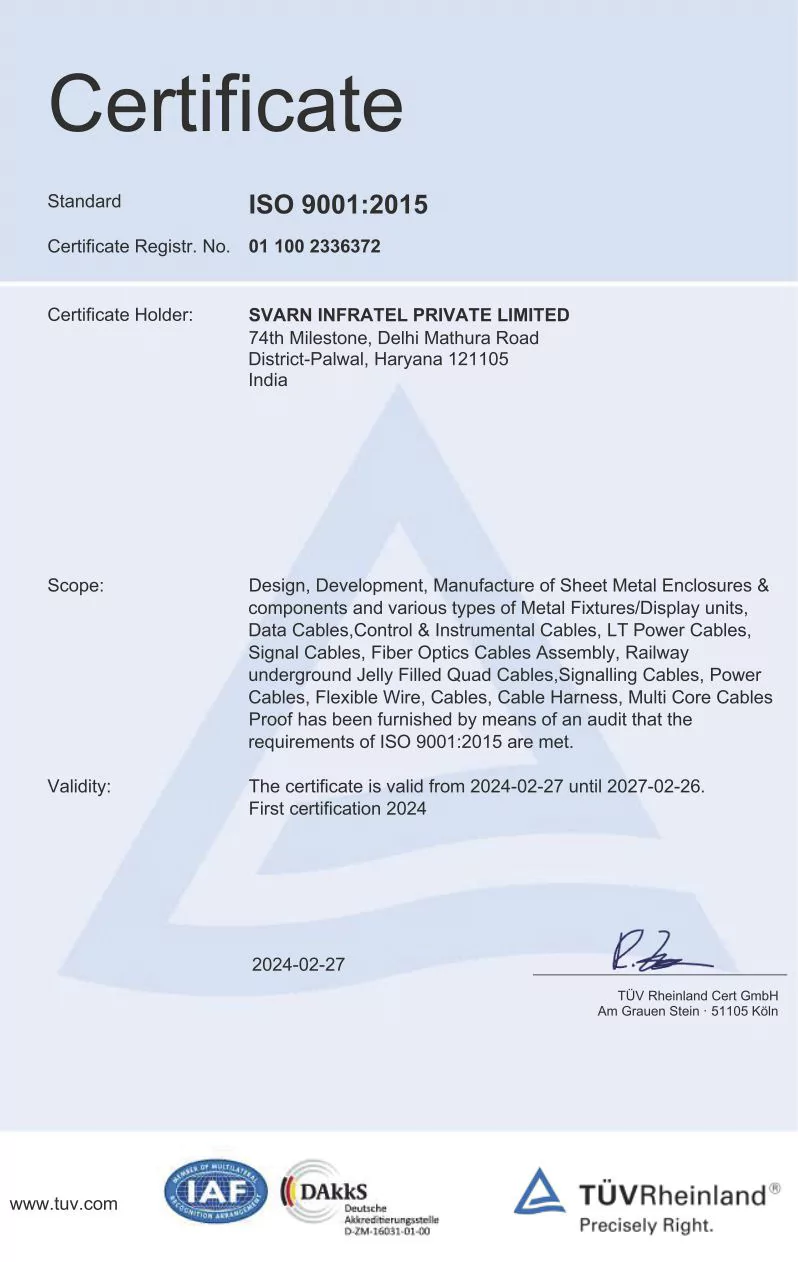

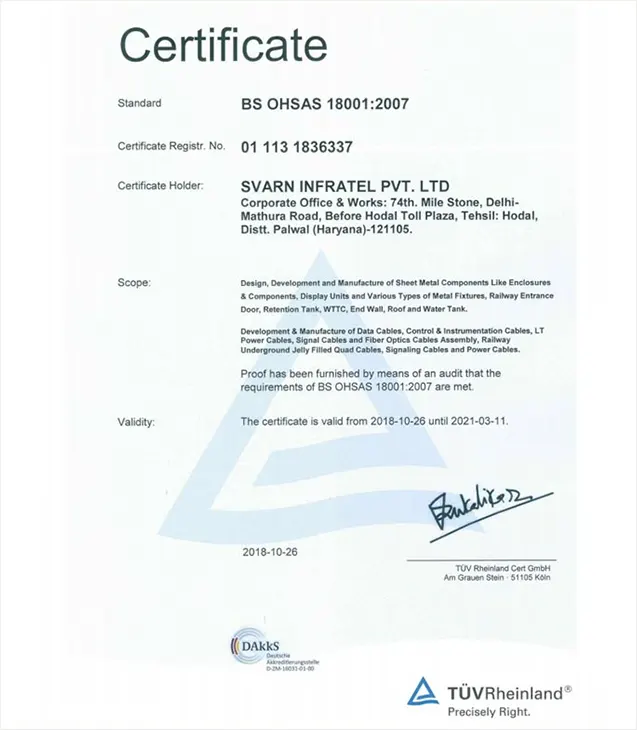

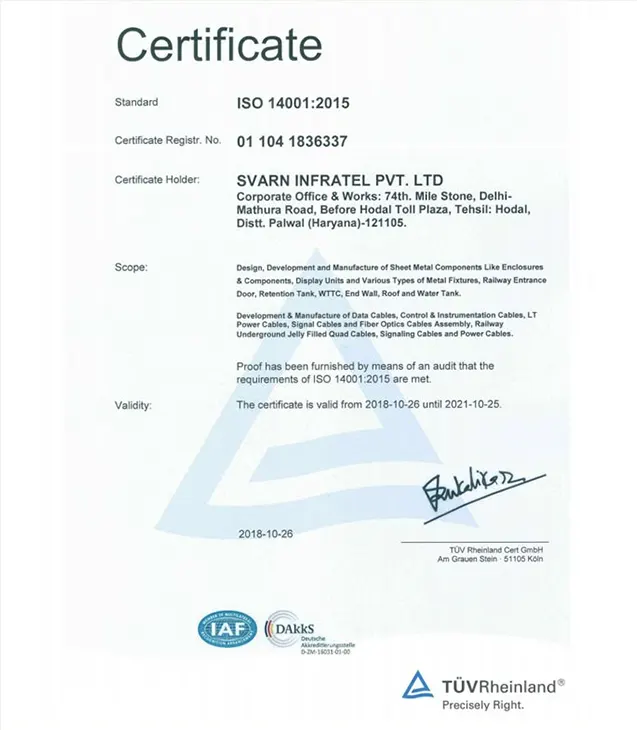

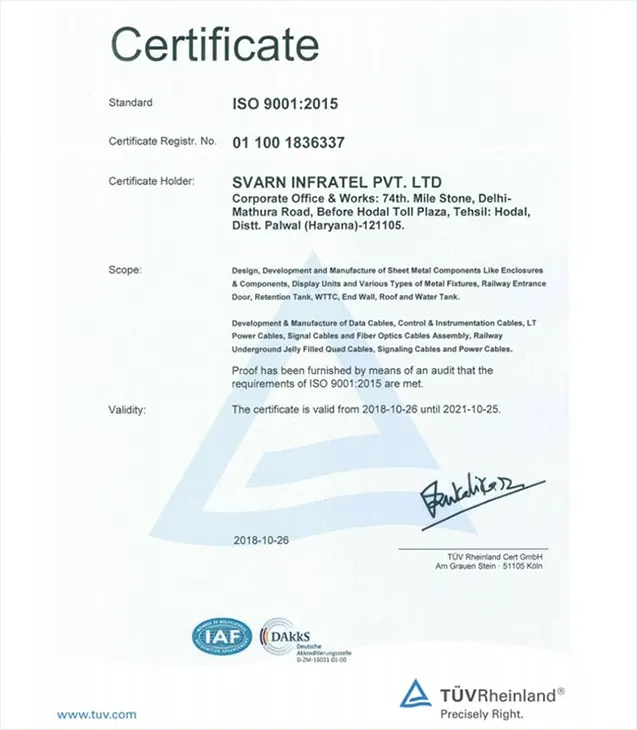

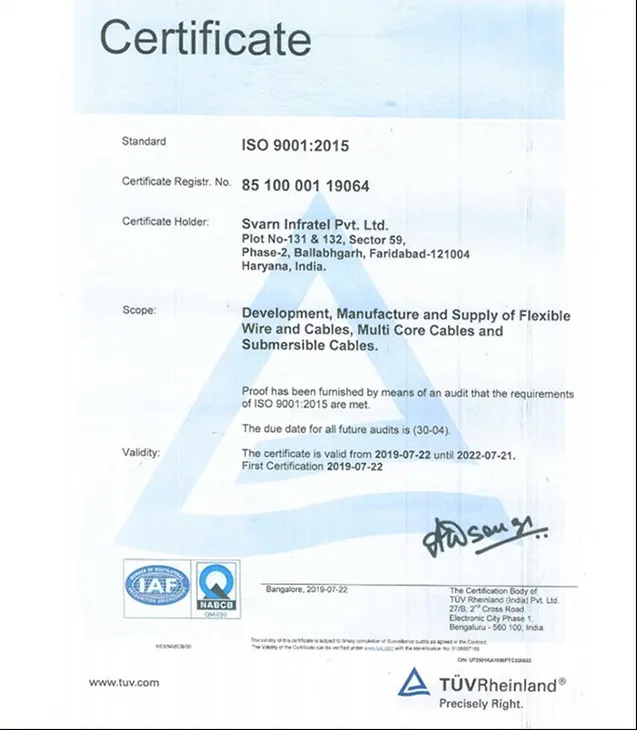

Quality Parameters

To provide superior quality, our products undergo stringent monitoring throughout the entire production process right from the procurement of raw materials to delivery of the finished products. We have a long-term supply agreement with premier suppliers to procure raw materials, ensuring the best quality at competitive prices. All procured raw materials are subject to pre-manufacturing quality tests at the commencement of each individual production cycle.

Quality Testing

- Transmission Parameter Test

- Oxygen Index Test

- Smoke Density Test

- Circuit Integrity & Flammability Test

Equipment and Facilities